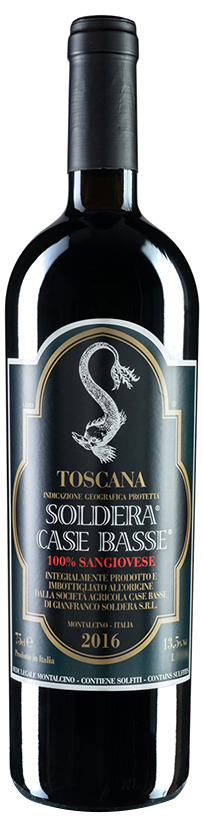

Toscana IGP

Soldera® Case Basse® – 100% Sangiovese – 2016 Vintage

Production: 14,511 bottles (0.75 litres) – 1,278 magnums (1.5 litres). All the bottles are numbered.

Production: 14,511 bottles (0.75 litres) – 1,278 magnums (1.5 litres). All the bottles are numbered.

Weather conditions in 2016 and timely agronomic management of the vineyards favoured excellent ripening of our Sangiovese, thanks to mild temperatures and careful control of the canopy and bunches during the various phenological stages of the vineyard.

The table shows the 116 days from flowering (26th May) to the harvest (starting 20th September), monitored by the weather station inside the winery. Let’s take a look in more detail.

Key:

– Thin line: Average ten-year weather data.

– Thick line: 2016 weather data.

– Green: Minimum daily temperature.

– Red: Maximum daily temperature.

– Blue: Total rainfall (in mm).

From flowering to veraison

Compared to the ten-year weather data averages, shown in the graph, the flowering-veraison stage, beginning at the end of May and lasting 63 days, was marked by a particularly mild June (from the 153rd to the 182nd day of the year) and constantly below-average temperatures. July (starting on the 183rd day of the year) had average temperatures and a slightly higher than average rainfall

From veraison to the harvest

The veraison-harvest stage began at the end of July (the 211th day of the year) and lasted 53 days. In August (starting the 214th day of the year), maximum temperatures were often lower than average while the rainfall was not far off the ten-year average. This weather trend, which lacked “heat waves”, helped the grapes to ripen properly. There were also mild temperatures and average rainfall in September (starting the 245th day of the year). However, canopy management and continual bunch selection, combined with carefully choosing the harvest period, which began on 20th September, enabled us to achieve excellent grapes for our wine.

At Case Basse, the 10 hectares of vineyards are planted in a complex ecosystem, made up of a great variety of other plants, animals and insects. Agronomic management is based on maintaining biodiversity, through the skilful and balanced use of science, technology, culture and tradition.

Budbreak

From the beginning of April, when the first shoots appeared, we constantly monitored each vine together with experts in phytosanitary management of vineyards. The only plant protection products allowed are copper and sulphur, but only in the necessary quantities and respecting the vinegrowing ecosystem. Care, measure, devotion, consistency.

Shoot thinning and bunch thinning

Canopy management and bunch selection are essential operations for obtaining very high-quality grapes: this year shoot thinning and bunch thinning started early, during the first few days of May.

The shoots are never cut (“topped”) but sheaved above the plants on special frames. This practice has a dual function:

Ripening

We also work on the precious bunches during the ripening stage, with a constant and well-thought-out selection to favour top fruit quality.

During the second half of August, we removed the basal leaves covering the bunches for better ventilation and lower stagnation of humidity: frequent rain could have encouraged fungal diseases.

And so, excess bunches were removed by hand, as well as those that were slightly damaged, and placed outside of the vine row to protect the healthy bunches.

Weekly microbiological and chemical analyses, which began in August, guaranteed the ripening trend and verified the excellent plant health of our 2016 Sangiovese.

When to establish the best time to harvest the grapes?

Sensory assessment and chemical-physical indications on ripening levels identify the right time to pick the grapes.

Which parameters should be monitored?

In technological terms: sugars, acidity and pH; in phenolic terms: potential and extractable anthocyanins, polyphenols, ripeness of grape seeds.

This information, together with invaluable tastings, established the idealmoment: we began harvesting on 20th September.

Once bunches have been selected and hand-picked, they arrive at the cellar in small crates, the ideal container to prevent them from being crushed, and laid on the selection table, where they are selected by expert hands.

This is when the berries are separated from the stems. A conveyor belt carries the bunches to the vibrating destemmer, which gently detaches the berries and sorts them by size: unsuitable ones are discarded.

The intact berries are manually checked one last time on the selection belt. Specialised workers carry out the final selection, discarding unsuitable ones. Only the fruit that passes all these stages will go into the fermentation vat.

Our Sangiovese ferments in truncated-cone-shaped Slavonian oak vats of over 100 HL.

Spontaneous fermentation

This enables us to reduce human intervention on natural processes to a minimum:

Daily chemical and microbiological analyses, as well as monitoring the fermentation temperature, determine how and when to do pumping over.

Why is spontaneous fermentation important?

Spontaneous fermentation processes guarantee a high level of biological variety; it is the yeasts, in fact, that ferment sugars to produce alcohol, as well as all those molecules that form the sensory structure of a wine. The different species of yeasts that characterise spontaneous fermentation contribute to the chemical complexity of the wine. This is what takes place inside our vats.

Which yeasts and how many?

For the 2016 wine, the first stages of the spontaneous fermentation process were carried out by non-Saccharomyces yeasts (Kloeckera apiculata and Starmerella bacillaris), which reached about 3 million cells per millilitre. These yeasts are normally present on grapes and are high producers of glycerol, a substance that enhances the “body” of a wine, as well as esters which distinguish the bouquet.

From the fourth day of fermentation, the wine yeast par excellence, Saccharomyces cerevisiae, gained the upper hand (about 5% of alcohol in volume) and was able to complete fermentation of grape sugars. It reached a maximum population of about 90 million cells per millilitre.

The spontaneous fermentation process lasted about 2 weeks.

Turning malic acid, which is naturally present in wine, into lactic acid: it is with malolactic fermentation, carried out by lactic acid bacteria, that the wine takes on a softer taste and forms all those compounds that contribute to the natural maturation process of wine.

Malolactic fermentation of the 2016 wine began naturally, soon after devatting, and lasted for about 3 weeks. The dominant microbial species was Oenococcus oeni, the lactic acid bacteria that commonly carries out malolactic fermentation in wine.

Once the fermentation stage has come to an end, the wine is placed in large Slavonian oak barrels to age for about 45 months: it is a period of watchful waiting where we carried out chemical and microbiological analyses on a monthly basis and never observed any microbial activity or populations that might have led to irregularities.

Frequent controls significantly reduced human intervention: we only carried out racking and sulphiting when necessary, so as to keep our wine’s taste richness as intact as possible.

No chemicophysical pretreatment, no clarification and/or filtration when entering the bottle: in fact, the wine had stable values, both chemically and microbiologically.

Once bottled, it rested in the cellar for over 6 months before being marketed.

Some data at the time of bottling

Care and attention to detail are also crucial when storing a wine, which is why we know that the choice of bottle and cork are fundamental.

Our special Bordeaux bottle series

The shape, colour, weight and proportions make our “Special series 15 Soldera Case Basse” 75-cl Bordeaux bottle the best one for our wine, even after several years.

All thanks to

The cork

We only use 26/50 mm corks, which guarantee a perfect match inside of the neck of our Bordeaux bottle: very high-quality corks, every aspect is meticulously selected.

Storage and serving temperature

Store the bottle vertically, at a temperature of 12°-16°C, in a well-ventilated environment with at least 70% humidity. Avoid sudden changes in temperature and direct sunlight.

We recommend serving our Toscana IGP Soldera Case Basse at 17° to 18°C, the ideal temperature for enjoying its aromas and taste.